Press Releases / News

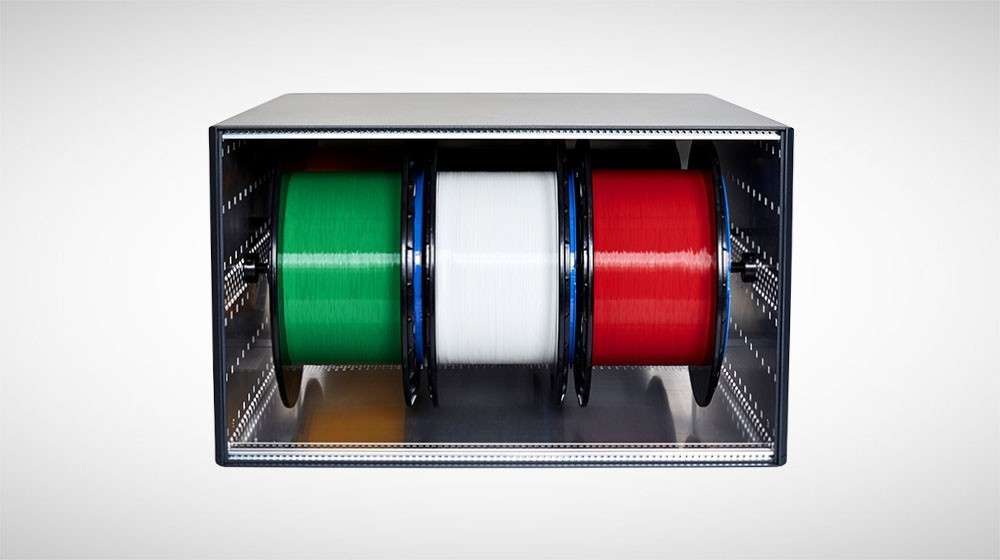

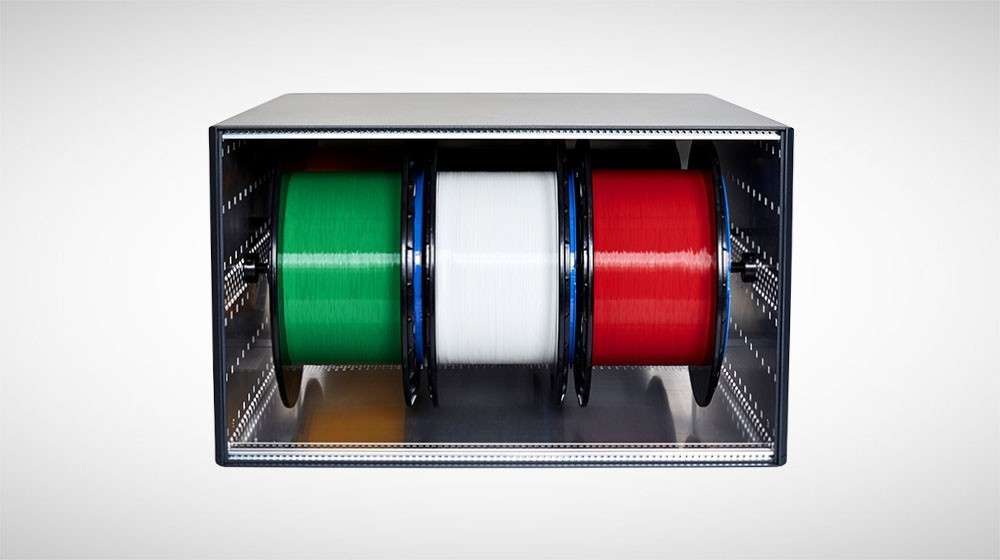

fionec launches Fiber Test Box Configurator18|11|2021fionec’s newly developed configurator makes it easy to configure the Fiber Test Box with just a few clicks. Fiber length, connectors and box type are freely selectable. The configurator helps you to quickly find an individual solution in just a few steps. The Fiber Test Box holds up to 6 fiber spools with a total length of 150 km and is ideally suited to use Corning® fiber optics for simulations, tests and demo applications in a safe and space-saving way. |

|

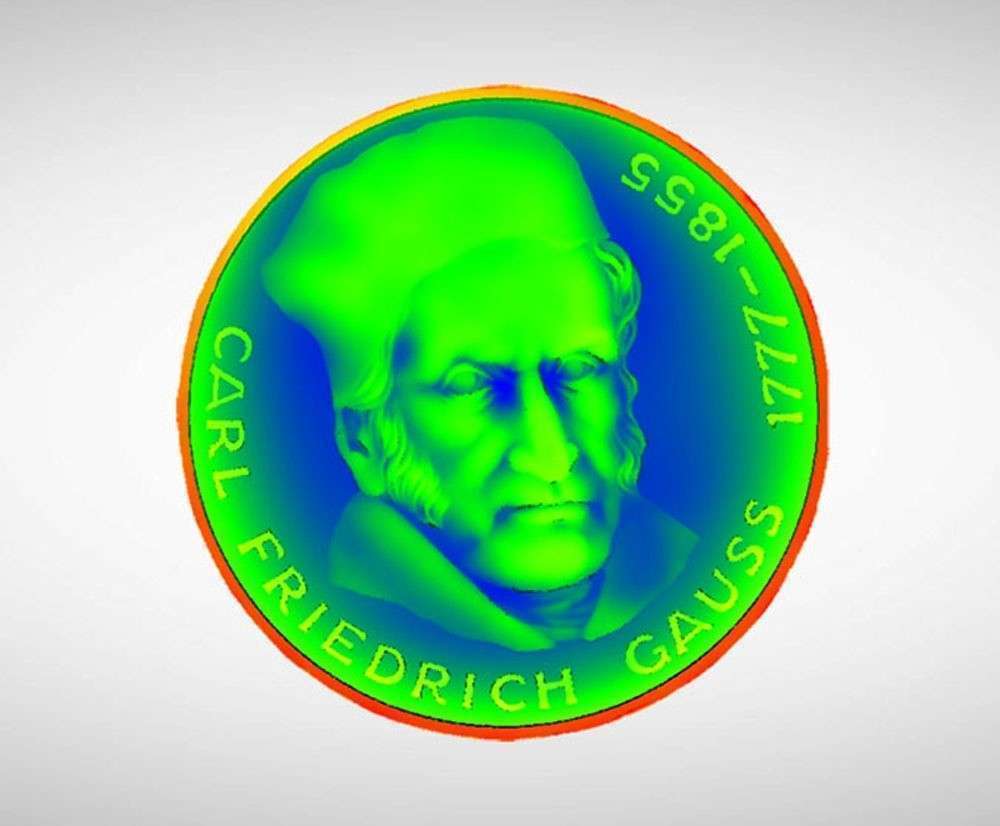

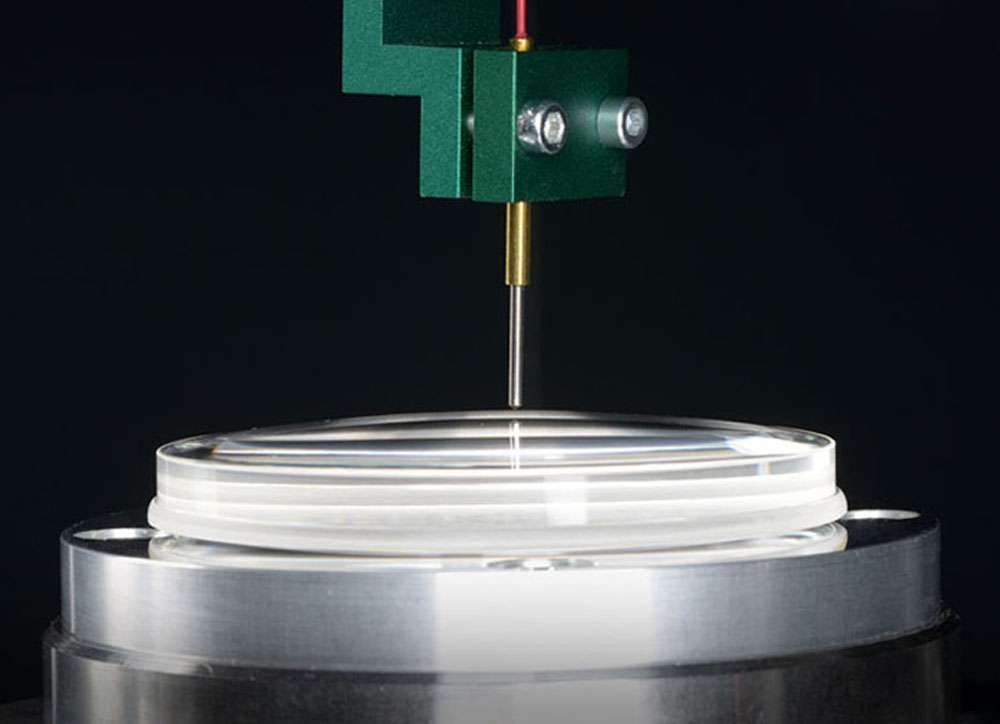

Fiber optic measuring system FDM – Unrivaled measurements in micro-drilled holes08|11|2021The FDM measurement system provides unique possibilities for borehole inspection. For example, copper layers in multilayer circuit boards can be determined in a contactless and non-destructive way, surface quality (roughness) and drilling quality of a hole can be assessed and precise depth measurement can be performed. The FDM sensor technology from fionec convinces with the high measuring frequency of up to 20 kHz. Through miniaturization of the measuring probes to diameters of up to 80 μm as standard, even the smallest micro-drilled holes can be inspected. The integration of the technology into coordinate measuring machines (CMM) of our partners is available. |

|

DataViewer – Data analysis made easy30|09|2021Challenging measurement tasks lead to more and more complex measurements. Complex and / or time-intensive measurements generate large data series that have to be analyzed and visualized. DataViewer, offered by fionec, is the perfect software for a straightforward 2D-visualization and the easy processing of large data series. A package for calculating roughness values in compliance with the prevalent DIN EN ISO standards is available as an option. |

|

Fiber optic measuring systems – FDM series23|09|2021Whether in the automotive industry, optical technologies or medical technology – optical measuring systems have become essential in many areas. In particular, optical measuring methods are used for measurements in the (sub-)micrometer range. In addition, increasing requirements are leading to more demanding measurement tasks. The fiber optic measurement systems (FDM) developed by fionec GmbH address a wide range of applications and usages thanks to the high-precision measurement principle. |

|

Fiber Test Box – Optical fibers fully protected14|09|2021The Fiber Test Box is the ideal solution to use fiber optics for simulations, tests and demo applications in an efficient and space-saving way. With only 6 height units, the 19-inch enclosure offers space for a maximum of 6 fiber spools with up to 150 km in total length. Fiber type, fiber length and connectors can be configured individually. Whether as a desktop unit or rack-mounted, the robust Fiber Test Box combines customized configuration with optimal protection. |

|

Smart technical instructions – fionec starts research project AdaptAR19|08|2020Industry 4.0 is AI-driven, digital and automated. Technical documentation, on the other hand, remains largely static and inflexible relics in this modern production world. From July 15, fionec is therefore supporting the joint project AdaptAR. The aim of the research project is to develop smart and interactive instructions and services that accompany the entire product life cycle from production to application. fionec is particularly dedicated to the modularization and linking of technical information. The objective is to create a database-supported document that is continuously updated in the event of technical changes. The individualization of technical documents is also to be improved. Since fionec’s measuring systems and probes are largely subject to customer-specific adaptations, a lot of time and effort is spent on creating individual construction and operating manuals. The modular and digital preparation of the information would offer significantly more flexibility and save resources. An extension of smart documentation to include augmented reality elements is also being considered. Information packages could be accessed in a mobile and application-specific way. The comparatively new AR technologies could enable interactions between actors and between users and products. The AdaptAR research project is scheduled to run for three years (2020 to 2023) and is funded as part of the BMBF’s “Innovationen für die Produktion, Dienstleistung und Arbeit von morgen” research program. |

|

One million measurement values per second27|02|2019fionec and the University of Kassel, Department of Metrology, are developing robust production metrology for nanometer-precise high-speed measurements up to 1 MHz. Focusing lenses with different NA allow optionally high lateral resolutions (at high NA ≈ 0.5) or large working distances of several mm (at smaller NA). Thanks to dynamic signal evaluation, measurements on low-reflecting measurement objects or components with steep edges are possible. The new sensor technology is robust, easy to operate and can probably be offered at a significantly lower cost than currently comparable competitor systems. The FIPOF research project is scheduled to run for two and a half years (01.01.2019 – 30.06.2021) and is funded by the BMWi as part of the ZIM initiative. |

|

Frank Depiereux appointed as AiF-Reviewer14|12|2018fionec Managing Director Dr. Frank Depiereux will be supporting the German Federation of Industrial Research Associations (AiF) as a reviewer starting in 2019. As an expert in metrology and sensor systems, Depiereux will evaluate research proposals and projects of the Industrial Joint Research and Development (IGF). He will consult and decide on discussion-worthy projects with other experts from industry and science at regular reviewer group meetings. Successful applications are qualified for funding from the Federal Ministry for Economic Affairs and Energy. The activity as an AiF reviewer is on an honorary basis. |

|

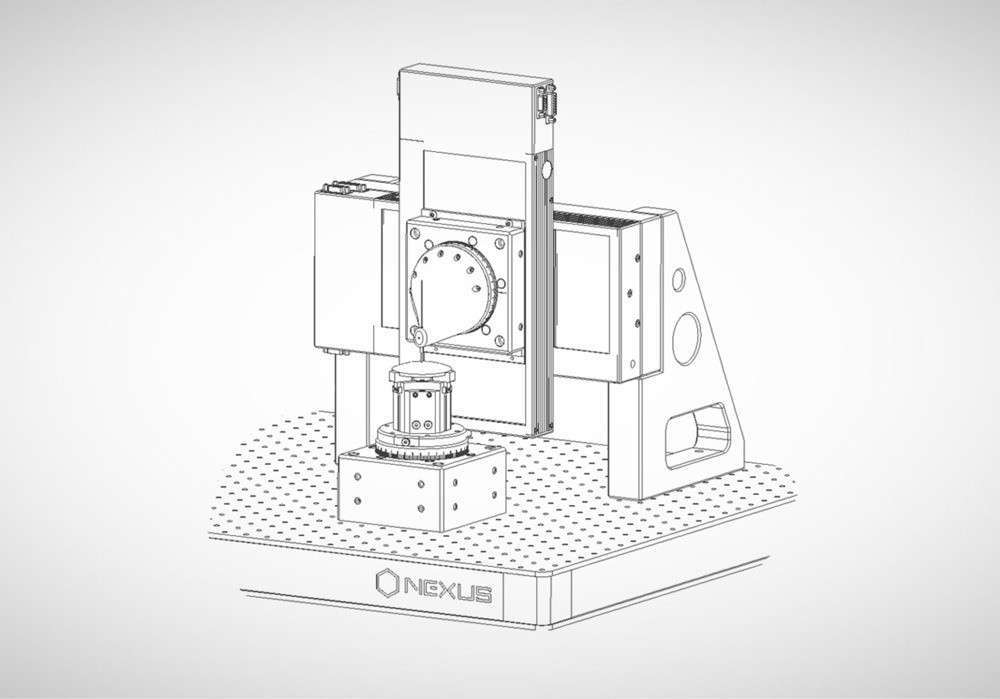

Non-contact inspection of complex optical components19|06|2017Innovative optics with complex geometries broaden the scope for innovative manufacturing processes – and present new challenges for metrology. In the current Photonik issue (03/2017), fionec and the Fraunhofer Institute for Production Technology (IPT) present a highly accurate fiber-optic measurement system and a precision-guided kinematic unit. The combination of both makes it possible to perform a fast, non-destructive roughness measurement and a 100 % inspection at the production line. You can download the complete article here (only available in German). |

|

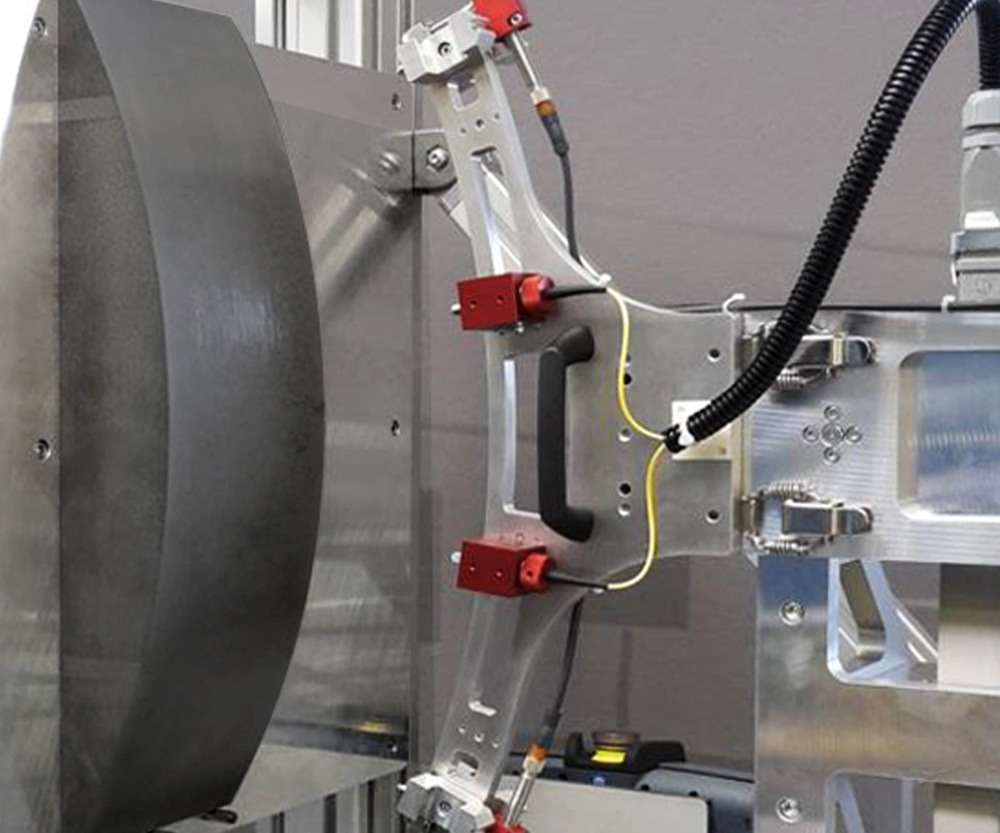

Measurement for large diameters07|12|2016With the development of fully functional laboratory samples for fiber optic measuring systems, the technology companies fionec and Awetis are setting new standards in the determination of diameters of large components. In the future, the BMBF-funded FiberGauge project will enable precise and convenient testing of shafts, rollers and other molded cylinders with an inner or outer diameter of more than one meter. “At the midpoint of our project, we have achieved all planned targets and in some cases even exceeded them,” states Frank Depiereux, Managing Director of fionec GmbH and head of the joint project. Until now, mechanical measurements by hand have been common for determining large diameters. This manual process is relatively inconvenient. The project consortium around fionec GmbH and Awetis GmbH has therefore designed compact measuring heads with fiber optic sensors. The new technology can be used both in mobile handheld measuring devices and integrated into automated processes. Using light waves, several sensors simultaneously scan the geometry of the component. The measurements take less than five seconds. The results can be used to calculate inner and outer diameters between one and six meters with micrometer accuracy. The new measuring equipment is of particular interest in plant and mechanical engineering, as well as in turbine shaft and bearing production. The technology group Siemens, the industrial supplier FCMD and the measuring equipment manufacturer Kordt are therefore accompanying the project as associated partners. The innovative approach of the project enables us to reduce non-value-adding non-productive times in the production of our components – while maintaining the same quality. This is achieved primarily through the significantly easier handling of the measuring system,” says Dr.-Ing. Mario Dewald, head of the Technology Group in Siemens steam turbine production at the Mülheim site. Until completion of the project in March 2018, fionec and Awetis will now further develop the evaluation and user software as well as the control system and interfaces. In addition, the calibration of the test parts and the design of measuring devices for further diameter sizes are on the agenda. The FiberGauge project is funded by the German Federal Ministry of Education and Research in the funding initiative „KMU-innovativ: Optische Technologien“ within the program “Photonik Forschung Deutschland” until March 31, 2018 with an amount of about 840,000 Euros. Further informationen (only available in German): Steckbrief BMBF-Verbundprojekt FiberGauge (.pdf) |

|

fionec promotes excellence18|11|2016fionec sponsors a one-year scholarship for Ramona Scheffer, a 22-year-old architecture student at RWTH Aachen University. Managing Director Frank Depiereux states that the promotion of young skilled workers is important. “Know-how and innovative ideas are the driver of our economy. That’s why we are very interested in the education of excellent specialists. With the scholarship, we want to create the right framework conditions,” explained the entrepreneur. The scholarship awarded by fionec is part of the Education Fund, the scholarship program of RWTH Aachen University. In the 2016/2017 academic year, a total of 561 particularly high performing students will receive financial support from these funds. The ceremonial presentation of the certificates took place on November 18, 2016 in the Coronation Hall of Aachen City Hall. |

|

15|01|2015

|

|